What is Rock Wool Sandwich Panel?

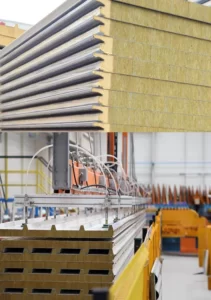

Rock wool sandwich panels are composite panels consisting of two layers of metal panels (color-coated steel/stainless steel) with a rock wool core.

The “sandwich” structure is formed using a high-strength adhesive and hot-pressed.

They are commonly used in industrial plants, logistics warehouses, cold storage facilities, cleanrooms, gymnasiums, and other buildings.

Key Advantages of Rock Wool Sandwich Panels:

1. Fire Resistance

A1-grade non-combustible material with a melting point >1000°C and CE certification, as well as international asbestos-free certifications.

2. Thermal and Sound Insulation

Low thermal conductivity (0.040 W/m·K) reduces air conditioning energy consumption by over 30%.

Sound insulation of 30dB makes them suitable for noise-sensitive areas.

3. Environmental Protection and Durability

CFC/HCFC-free, meeting LEED certification requirements.

Corrosion- and mold-resistant, with a service life of over 20 years.

BESINO Rock Wool Sandwich Panel Product Line:

FAQ

“Does rock wool sandwich panels absorb water?”

→ Answer: Rock wool itself has a water repellency of >98%, but the joints must be properly sealed.

“How long does the installation take?”

→ Answer: About 7-10 days for a 1,000 square meter project (saving 30% time compared to other materials).