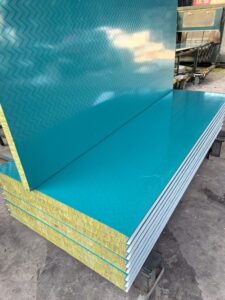

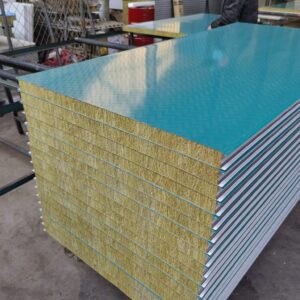

Rock wool sandwich panels are a type of high-performance composite panel widely used in the construction industry. They are made of two metal panels (such as galvanized steel sheets) and a rock wool core material filled in between, bonded together with a high-strength adhesive.

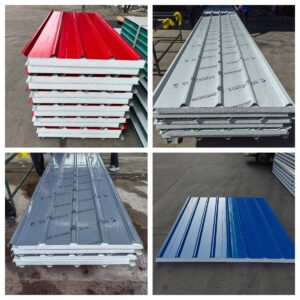

Standard colors include: red, blue, white, and gray.

Custom colors are available; today’s product is in turquoise blue.

Characteristics of rock wool sandwich panels

1. Excellent Fire Resistance

Class A Non-combustible Material: Rock wool is made from natural basalt melted at high temperatures, with a melting point exceeding 1000℃, classifying it as a Class A non-combustible material and meeting stringent building fire safety standards.

Flame Retardant and Heat Insulation: It does not release toxic fumes when exposed to fire and effectively prevents the spread of flames, commonly used in fire compartments, firewalls, and other critical areas.

2. Superior Thermal Insulation

Low Thermal Conductivity: The internal structure of rock wool is filled with air, resulting in a low thermal conductivity (typically approximately 0.036~0.042 W/(m·K)), significantly reducing heat transfer.

Energy Saving and Environmental Protection: Effectively maintains stable indoor temperature, reducing air conditioning and heating energy consumption, suitable for industrial plants, cold storage facilities, etc., where high insulation requirements are necessary.

3. Good Sound Insulation

Sound Absorption and Noise Reduction: The porous fiber structure absorbs sound wave energy, reducing airborne and structural sound transmission, commonly used in machine rooms, workshops, and other places requiring noise control.

4. Lightweight and High-Strength Structure

Lightweight: Low density (typically 50-120 kg/m³ for core material), reducing building load.

High Strength: The combination of metal panels and rock wool core provides high compressive and flexural strength, suitable for large-span roofs or walls.

5. Durability and Corrosion Resistance

Strong Weather Resistance: Metal panels are often galvanized or coated, offering excellent corrosion resistance and weather resistance, suitable for outdoor environments.

Moisture and Mildew Proof: Rock wool core material has a high water repellency rate (≥98%), making it resistant to moisture and deformation over long-term use.

6. Convenient and Efficient Installation

Prefabricated Production: Standardized factory manufacturing ensures precise dimensions and direct on-site installation, resulting in a short construction period.

Flexible Design: Customizable length, thickness, and panel material to meet diverse architectural design requirements.

7. Environmentally Friendly and Healthy

Non-toxic and Harmless: Rock wool raw materials are natural minerals, free of asbestos, CFCs, and other harmful substances.

Recyclable: Both the metal panels and rock wool are recyclable, aligning with green building principles.

Application Areas:

Industrial Buildings: Factories, warehouses, cleanrooms.

Public Facilities: Stadiums, exhibition centers, hospitals.

Commercial Buildings: Shopping malls, office buildings.

Special Locations: Cold storage facilities, laboratories, areas with high fire safety requirements.

Precautions:

Moisture Protection: Avoid prolonged exposure of rock wool to damp environments during construction; seal joints.

Joint Treatment: Pay attention to details such as panel joints, doors, and windows during installation to ensure overall airtightness and watertightness.

Rock wool sandwich panels, with their multiple advantages including fire resistance, thermal insulation, and lightweight, have become a widely used enclosure material in modern industrial and civil buildings, especially indispensable in projects prioritizing safety and energy conservation.

Copyright © 2023 QINGDAO BESINO Company Limited All rights reserved.